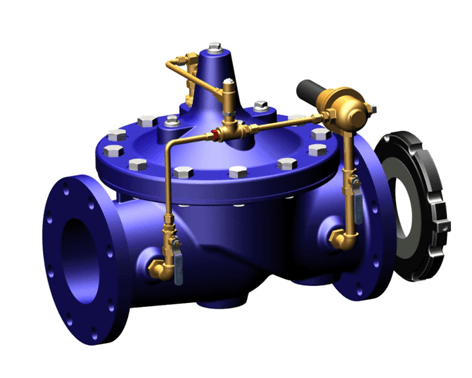

An automatic recycling valve is made up of connections of various parts. For instance, the diaphragm control valve is one of such parts connected into a multiplicity of piping systems. It plays a critical role in ensuring the efficient working of the valve. However, there are different connection types of diaphragm valves, as discussed in this article.

- Threaded connections

Threaded diaphragm type of valve has external and internal threads that are used to screw the pipe over or into the valve end. The technique works effectively, and it is one of the commonly used. The approach used is simple, and therefore, it is easy to repair when necessary.

- Compression fitting connections

Similarly, compression fitting is another control valve connection used in a diaphragm connection commonly used in pipes. However, this type of connection is made without threading or soldering. As a way of forming the seal, one net is tightened to compress the washer around the second pipe. Consequently, a watertight closure is formed.

- Clamp flange connections

Diaphragm valve manufacturers designed clamp flanges connections to help control the inflow and outflow in a pipe. It uses spring hinge flanges, clamp flanges, to wrap around the pipe and make a connection in return. Consequently, the inflow and outflow can be controlled using the connection in question.

- Bolt flanges connection

Likewise, diaphragm type in question is used in many piping works. The connections are used at the outlet or inlet of the valve to control the flow. However, the connection can be in different sizes depending on the user’s specifications. For instance, you can make a 1 2 inch diaphragm valve if you do not have a wide range of flow rate.

- Buttweld connections

A butt weld automatic diaphragm valve is another similar connection that holds a joint between two sections. Subsequently, the two are butted together without an interlock or overlapping. They form a tight joint that prevents the passage of any substance.

- Socket weld/Solder connections

The fifth diaphragm type of valves in piping is the socket solder or weld. In this method, the connection is made by soldering two pieces together tightly. As a result, the joining prevents the passage, thus making a valve. The technique is simple to use and maintain, as well.

- Metal face seal connections

In this type of connection, a sandwiched metal gasket between two fittings parts is used. Consequently, a face seal is formed on the two sides of the fitting, thus blocking the flow. The industrial diaphragm valve is commonly used in various fields.

In conclusion There are various techniques used to make diaphragm control valves to control the flow in pipes. Although they all serve the same purpose, the connections are made differently. Discussed above are various types of diaphragm connections and their working principles. They can be used as a guideline to enable you to make a decision on the type of connection that would suit you better.