Rapid prototyping or manufacturing techniques and equipment have gone a long way in making the formulation of various products a lot easier. The various types of rapid manufacturing techniques and equipment are also highly appreciated. This is because there is a type suitable for just about any Project you might need to embark on.

The FDM and the SLM have been used in the automobile industry for quite some time now. The components fabricated from these processes could be almost as durable as the good old` fashioned smithing process. “Almost” being the keyword in the previous sentence. Ddprototype is one of the more trusted sources of rapid prototyping today.

But some people are not quite sure about the exact advantages and disadvantages of the rapid manufacturing processes. Hopefully, this article will shed a sufficient amount of light on the advantages and disadvantages of rapid prototyping techniques. But we will also briefly turn our attention to a few other interesting matters concerning rapid manufacturing techniques. But to better understand these advantages and disadvantages we will have to start at the top.

What do you Know About Rapid Prototyping Techniques?

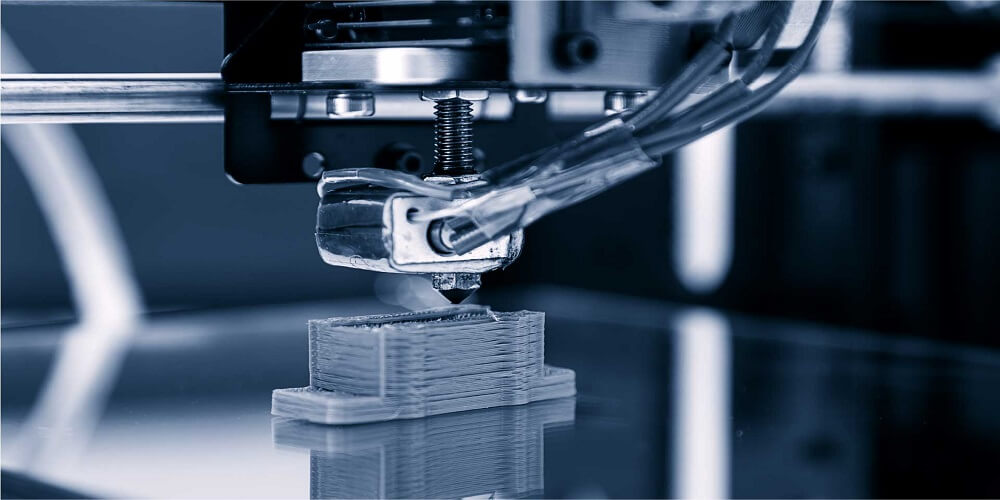

Did you know that rapid manufacturing techniques are a subset of a branch of manufacturing? Yes, repeat manufacturing techniques are under the additive formulation method of manufacturing. These addictive formulation techniques make use of “layering” in their formulation.

There are various methods through which clearing can be used. These various methods are well reflected in the fact that there are various techniques for employee rapid manufacturing. These various techniques lead to the variety in the costs of the various techniques. Some techniques require expensive materials to formulate durable and stable intricate parts and components.

The “ink” or “powder” used in certain types of rapid manufacturing could be said to be particularly expensive. this is because, these powders could be derived from metals such as titanium, aluminum, stainless steel, and many more.

On the other hand, some forms of rapid manufacturing do not require such expensive materials. These are the forms of rapid manufacturing that are mainly used in education settings as well as private projects.

Advantages of Rapid Prototyping

- The very first advantage would be the fact that there is less restriction on what can be achieved. Usually, professionals restrict themselves in their designs as a result of geometrical issues and complications. But we rapid manufacturing such restrictions are very much reduced.

- The formulation of intricate and complex designs is one advantage that just cannot be left out. With advanced rapid manufacturing techniques, geometrical issues can be largely solved. Some forms of rapid manufacturing and show a high degree of geometrical accuracy.

Disadvantages of Rapid Prototyping

- The very first characteristic of rapid manufacturing that discourages people is the cost of the materials. The material rapid manufacturing needs to fulfill certain criteria to be usable.

- The second issue will be the time taken in the formulation process. The addictive formulation method of manufacturing is accurate to a large extent, yes. However, it is much slower than conventional printing methods.

- Maintenance could also be a challenge. Maintenance needs to be carried out frequently to extend the lifespan of your machine.

Conclusion

There are many more advantages as well as disadvantages of rapid prototyping. But these are the basic factors when considering whether rapid manufacturing is for you or not.