Injection molding is the process used in manufacturing items the likes of plastic and toys. The process involves turning those materials into automotive body panels, cell phone cases, water bottles, and other items made of plastic. During the process of manufacturing, the plastic is converted then taken through a process called mold design. Through mold design for injection molding, the liquid plastic is forced into a mold or cures in a complicated process. Other than molten plastic, mold design can also be done on the melted glass. The mold design process determines the quality of the resulting products. This post intends to give you more mold design information.

The process of mold design

1. The thought processes

This initial step of the process determines the general flow of the entire process. For the mold design process to run successfully, mold manufacturers have to establish a streamlined process that covers all aspects and milestones, starting with the price quotation at the beginning of the process and the desired finished product at the end of mold design.

In the thought process, the inputs and outputs for each step of mold design have to be determined. The expectations of each stage and the final product also have to be clearly defined. The specific technologies and methods to be used in mold design, and the design of the final product also has to be determined during the thought process.

2. Quotation

This is where aspects like the material’s parameters for shrinkage, tip points, rotation, and other crucial elements are put down. The quote aims to provide the engineers and designers with an idea of how the job will be approached. For effectiveness, the quotation should be done by an experienced practitioner in the field because the quote determines the quality of the final product.

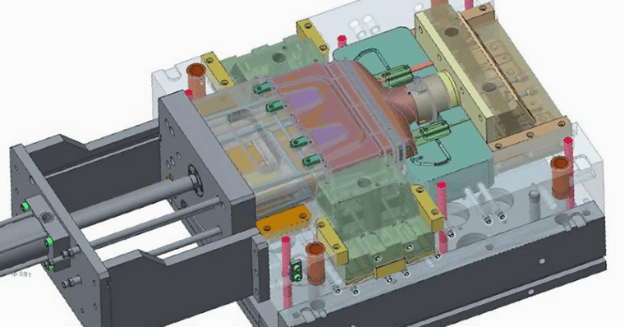

3. Design

The most common design for the mold design process is 3-D. Earlier, 2-D was the trend, but currently, every manufacturer in mold design is looking to employ solid 3-D models. 3-D designs make it easier for manufacturers to achieve the task of standardization and synchronization. It also aids in speeding up the process and the production of quality end products. Working with 3-D also allows the manufacturers to catch production issues as soon as they emerge hence allowing the issues to be resolved before they can affect the entire process negatively. With 3-D changes can also be made to the design promptly.

4. Making the Mold

Manufacturing here involves the use of several machines and a lot of skills. An injection molding machine comprises three primary units; the hopper, the heater, and the ram. These units work together to ensure the achievement of quality products. The manufacturers have the task of ensuring that these units are working correctly.

Final Word

Through mold design, manufacturers can achieve intricate designs that otherwise would not be possible. The process of mold design is intricate yet economical, and the volume of products that can be achieved through mold design is also incredible.