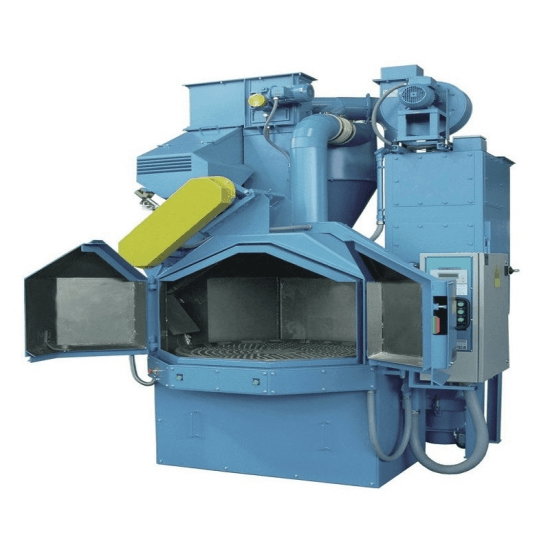

CNC is short for Computer Numerical Control. It is a modeling technique that emphasizes computer precision capacities over human efforts. A CNC milling machine uses a set of computerized instructions or codes to cut through the material to produce high-precision models and precision parts. Apart from being useful in industries, there are other wide applications where CNC milling can be very helpful. If you are a structural engineer or an artist, there is more to gain from CNC milling parts if you use it for your project.

Why use CNC milling for your project?

- Make models/prototypes faster

Since CNC milling parts automate the machining process, less amount of human effort is required. The mill works seamlessly and efficiently to produce models and prototypes as quickly as possible. This means you need less time than produced using manual methods. The CNC milling can help you complete your projects faster.

- Save cost

The manual machining process requires hiring expert technicians to manage different parts of the machine. CNC milling reduces the number of experts required to one or two per mill. You can also learn to operate the mill by yourself. Ultimately, the cost of starting and finishing the project is reduced. Money saved on modeling can be channeled into other essential aspects of the project to improve project quality and value.

- Stay safe

Since very little human effort is required on CNC mills, you can expect low cases of injuries to workers during operation. Unlike manual machining processes that expose technicians to lots of hazards, CNC mills are custom built with safety accessories. As the machine does the majority of the work, users only need to control and monitor the milling process from a safe distance.

- Quickly detect deficiencies

Most CNC mills make use of internal detectors to evaluate the integrity and quality of the model or prototype being produced. The machine can quickly draw the operator’s attention whenever corrective efforts are needed before the work is complete. Users can quickly make necessary adjustments in the process. This feature helps to give higher quality models and components in good time.

- Use materials you prefer

CNC mills are majorly known to use steel material. However, they can also use plastic, wood, acrylic wax, and other machining materials. This versatility makes CNC milling a helpful process when one is trying to find out which material better suits a model. Since the same machine can use the materials you are considering, you save costs and time in the process of finding the best material for your creation.

Conclusion

Although CNC mills are not perfect for producing tools en-masse, they are very useful if you need to create a particular tool for your project. CNC mills can do all that the regular milling machines can do. CNC mills add automation and precision to the equation, which makes it a veritable tool in the hands of many project designers and managers. As an individual, you can also use CNC mills to boost your creativity in design, arts, and architecture.