for reference purposes or for those who are not too familiar with the term, a blaster here refers to a machine or more specifically an excellent piece of equipment meant for increasing the durability of surfaces of metals. Blasters could be said to be part of an excellent piece of technology which functions by firing shots at a metal product in order to force out the impurities in the surface of the metal. The blaster is important in the shot blasting process. In that case, what then is shot blasting?

What is Shot Blasting?

Shot blasting is a technical procedure invented in order to clean, peen (strengthen) and polish steel and other metal products. This process is vital in just about every single industry that makes use of heavy metal machinery. These industries include the following but are not limited to:

- Automobile.

- Building ships in shipyards.

- Railways

- construction

- Bridge building and many more.

Types of Blasters

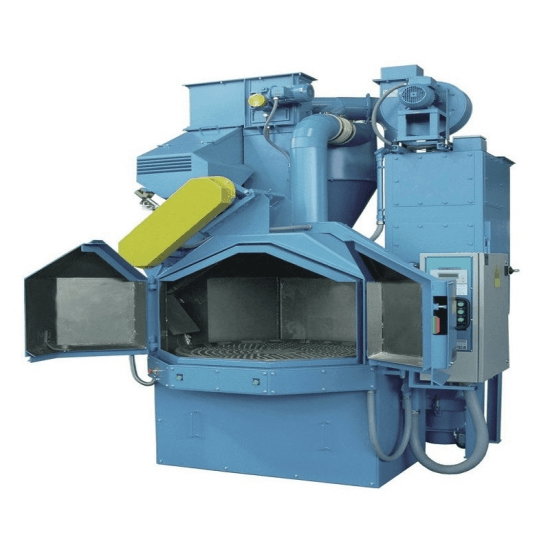

A common type of blaster is the wheel blaster. The wheel blaster does not operate on any kind of pressure. The two major forms of blasters are those for wet blasting and those for dry blasting. These are very similar, the only difference being the presence of fluid in the wet blasting.

The most prominent example of the dry blasting is the wheel blasting. Here the energy generated by the rotation of the electric motor of the turbine wheel is converted to kinetic energy. The force generated could vary from as little as 60 kg per minute (60kg/min) to as high as 1200 kg per minute (1200 kg/min).

We also have the use of air blasters in a process known as air blasting. This takes the form of a blast cabinet.

These blasters are usually paired with shots. These shots refer to abrasives which are made up of different materials. These include:

- Glass beads

- Sodium bicarbonate and other synthetic materials.

- Steel grits

- Aluminium pellets

- Silica sand

- Copper shots among others.

Blasters as part of the blasting process are vital because because they assist in giving the metal the required texture. This texture is what aids the metal product in retaining colour and other finishes. This ability to retain colour is due to the fact that the material is now more coarse to an extent.

The blaster is also important in increasing the toughness of the metal` surface. This is because, in the process of removing the impurities, the blaster also makes the surface more compact and coarse.

The impurities removed include:

- Rust

- Old paints

- Sand found on foundry pieces and others.

The machine with which the blaster is used is known as the blast machine, or shot blaster machine, or shoot blasting machine or wheel blasting machine/ equipment.

The machine is fully automated and is about 100 times faster than any manual procedure or method. This makes it the most convenient and safest method for surface polishing of steel products as well as other metal products or constructs. The impurities will be successfully removed, leaving behind a matte surface.