CNC machining services have been essential to the manufacturing sector for many years. The term “CNC,” for “Computer Numerical Control,” describes a manufacturing procedure where computers regulate the motion of cutting tools to shape raw materials into finished goods. CNC machining has developed to become more sophisticated with the help of cnc machine metal to make high-quality components in huge quantities. Several of the trade secrets of CNC machining services will be revealed in this article.

The Key Is Precision

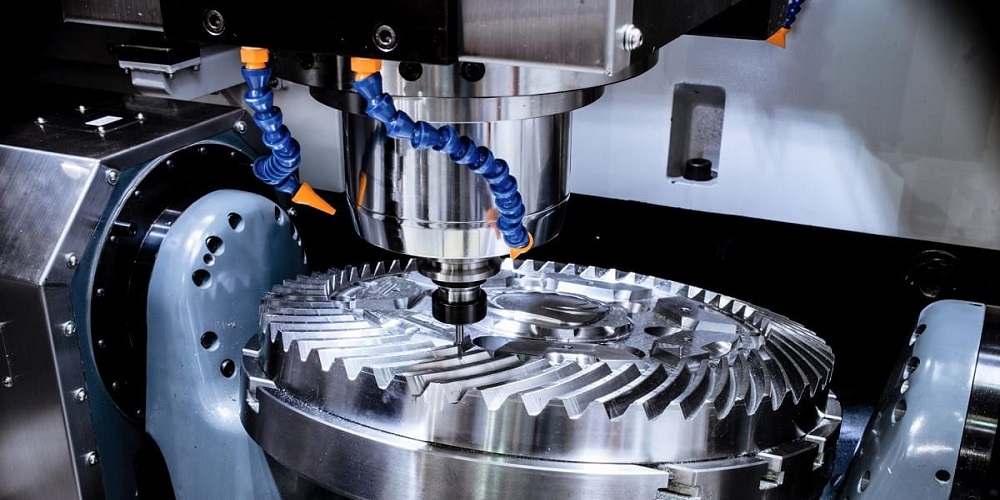

Precision is one of the most crucial elements of CNC machining. CNC machines can produce items with incredibly high accuracy, frequently within a few microns of the required dimensions. This level of accuracy is essential in sectors where components must fit together flawlessly or where slight deviations can drastically affect performance. To reach this degree of accuracy, CNC machines employ sophisticated software to regulate every part of the production process, from the cutting tools’ speed and direction to the coolant’s temperature and pressure

A Variety of Materials

Metals, polymers, and even composite materials may all be machined using CNC technology. Aluminum, steel, brass, and titanium are the most often used materials in CNC machining. However, this list is not exclusive. CNC machines may also operate with unusual materials like carbon fiber or tungsten, depending on the specifications of the final product. One of CNC machining’s major advantages is its adaptability, which enables producers to produce unique components for virtually any application.

Automatic Operations

Long durations of uninterrupted operation are possible with CNC machines. Once programmed with the design criteria, the machine may constantly run until the task is finished. Automation makes the final product more accurate and consistent while saving time and money. Each item is manufactured to the same specs because CNC machines are designed to check for mistakes and modify as needed.

Flexibility in Design

With CNC machining, there is a lot of design versatility available. The software used in CNC machining enables designers to produce sophisticated objects with exact dimensions and complex shapes. The CNC machine can generate the item from many angles and orientations, and the design software can create parts in either 2D or 3D. Because of its versatility, manufacturers can build objects that would be challenging or impossible to make using traditional production processes.

Rapid Prototyping

Rapid prototyping works best when using CNC machining services. Manufacturing companies may generate prototypes in hours or days rather than weeks or months since the machines can make parts rapidly and correctly. With the help of this approach, engineers and designers can swiftly test and enhance their creations, making adjustments as needed to increase functionality or performance.

Affordable Production

For big production runs, CNC machining services are also economically advantageous. The cost per part considerably falls once the design has been programmed into the CNC machine. The machine requires no extra setup or programming to continue producing parts. Because of this method, CNC machining is perfect for big production runs when cost-effectiveness is the main priority.

Continual Development

CNC machining services are always developing and getting better. Manufacturers can make higher-quality components more rapidly and cost-effectively because of the ongoing development of new software, materials, and production processes. The possibilities for what may be produced are almost endless as CNC machining technology develops.

Conclusion

The benefits of CNC machining services have brought about a revolution in the manufacturing sector. Due to its versatility in terms of materials it can work with and the speed and accuracy with which it can make complicated components, CNC machining has established itself as a vital tool for producers across practically all sectors. In the future, we may anticipate even more interesting innovations in CNC machining as technology develops.