NextSmartShip is a provider of fulfillment services to e-commerce businesses across the world with its headquarters in Shenzhen, China, an epicenter of global manufacturing and trade. NextSmartShip has fulfillment centers in Shenzhen, Hong Kong, United States, Europe, and Australia. They also work closely with FBA fulfillment centers.

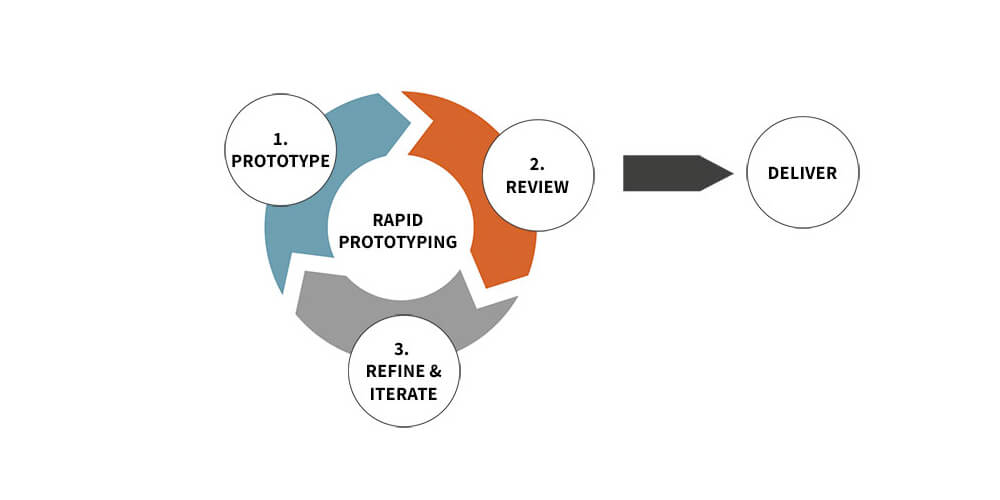

How does NextSmartShip work?

After identifying your manufacturer and getting your products made, get the QF products shipped to the NextSmartShip warehouse. NextSmartShip will receive cv products for any damages while still facilitating any returns. NextSmartShip will receive the inventory in the inventory management system, unpack and inspect the products for any damages while still facilitating any returns. When orders to your e-commerce store are placed, NextSmartShip picks, packs, add any additional outlined services, and then ships to customers anywhere in the world.

As orders are shipped, tracking numbers are auto-generated and sent to the customers via email to help them track their orders.

Apart from e-commerce fulfillment, NextSmartShip offers other services like crowdfunding fulfillment, FBA Prep services and subscription box fulfillment.

NextSmartShip crowdfunding fulfillment services help you fulfill orders and shipment for the backers’ reward. We will help you kick start reward fulfillment, IndieGoGo fulfillment, Groupon fulfillments, and Flash sales, among others.

Selling on Amazon has many benefits however, their “ready to be fulfilled” requirements can be quite a hassle. NextSmartShip runs point on your Amazon projects through our FBA Prep Services.

Our FBA Prep Service helps you to:-

- Get your items accepted and approved by Amazon when they keep on being rejected due to your requirements. We will ensure that your item meets all the Amazon requirements.

- Amazon has a lot of different requirements for different items. You do not need to worry about spending a lot of energy and time on that, NexSmartShip has you covered.

- Reduce your fulfillment cost. Amazon also provides FBA Prep, their overall cost is high. At NextSmartShip our handler’s fee is simple and affordable. We have a centralized inventory system that makes it easy to track your orders.

Get your Subscription box delivered on time with NextSmartShip and keep your customers happy. The subscription fulfillment niche is rapidly growing. With our experience in assisting many companies in subscription fulfillment, we are in a better position to assist you and your eCommerce business.

Advantages of using NextSmartship:-

- You will get up to 90days of free storage at our China warehouses, reducing your fulfillment cost.

- Inventory management with real-time monitoring and the ability to sync all your data.

- No fee is required to set up an account and receiving goods.

- A dedicated account manager who is a one on one customer assistant to help you every step of the way.

- Over 200 shipping destinations across the world. NextSmartShip will deliver your order anywhere in the world. We have fulfillment centers in the USA, Europe, China, and Australia.

- Flexible shipping options to choose from. We work with major international shipping couriers like DHL, Royal Mail, USPS, etc.

- Fully automated fulfillment system that is user friendly.