Rapid prototyping is a manufacturing technique used to fabricate physical parts using 3D computer-aided design (CAD). Prototypes are convenient for developers, users, designers, and investors to validate and communicate their ideas. The process involves collaboration among designers, managers, engineers, and end-users.

Rapid Prototyping Benefits

Being a manufacturing process, it has its share of pros and cons. Ideally, this technique reduces development time, reduces risk, improves user involvement, and reduces development costs. The major issue is that it requires skilled labor.

These are some of the advantages of rapid prototyping.

Quick Testing

With rapid prototyping, designers can iterate and test various design methods and ideas. Also, it allows for the use of intuitive visuals to complement verbal descriptions. Every person involved in the process will have a consistent understanding of important needs.

Time-saving

When designers employ rapid prototyping, they can get feedback quickly, which they can use to improve the final design. Moreover, the process helps minimize changes during product development and improves productivity.

Cost-effective

Experts at Rapid Done argue that when rapid prototyping tests are done at the early stages of product development, you can save a lot of time and cost (Contact RapidDone to know more ). That is because time spent on back-end product architecture is considerably reduced. The prototype can be tested before it is available for development.

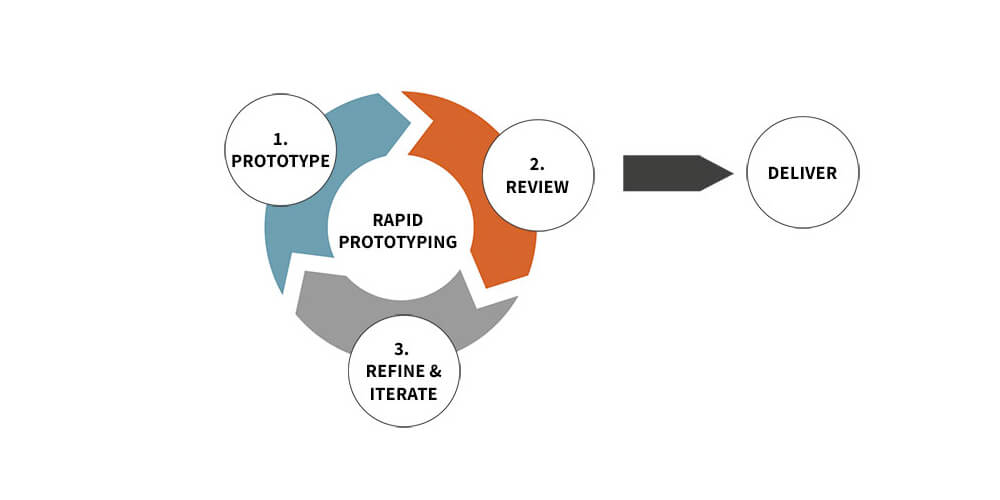

Rapid Prototyping Process

Brainstorming

Rapid prototyping starts with brainstorming. It is an effective way of building a profile for your parts and products. In fact, failure is common in the process, and brainstorming allows designers to work on both bad and good ideas in a low-cost, safe manner before investing energy and time into the development of prototypes.

Production of 3D Files

Production of three-dimensional files of the product is necessary. The use of 2D plans is recommended for parts with critical tolerances. Also, project specifications ought to be drawn up. Specifications depend on both technical constraints and the end-use of the product. After creating specifications and 3D files, a rapid prototyping company comes in.

Costing

Every rapid prototyping project is costed by a prototyping company based on the technical features and quantity of parts. Features consist mainly of material, geometry, and finish of a prototype. This step is that it helps determine the feasibility of the project. At this stage, there is room for modification of the parts.

Evaluation

Prototypes are shared with users, designers, and experts to evaluate whether they meet the intended purposes. This stage aims to establish that the final product performs the expected function. If the product is not found to be valid, it is returned to the first step of brainstorming.

The success of any given prototype depends on the prototyping technology used. Each technique has its competitive advantage in terms of speed, material compatibility, development stage, fidelity level, and cost. Rapid prototyping does not have to be limited to a single process. Multiple manufacturing processes can be used to assemble a prototype. The following are the common rapid prototyping technologies used:

CNC machining

Investment casting

Binder jetting

Stereolithography

Fused deposition modeling

Vacuum casting