The creation of models or sampling process for evaluation and testing of any item design is vital before the mass production of products. However, it’s a fact that creating a prototype can be quite expensive. A simple way of lowering the cost is through the use of CNC machining services. Below are the main advantages of using CNC machining orders for your sampling process instead of models.

- CNC Machining Services Is Material Friendly

Sometimes the production and manufacturing of products are interrupted because of a lack of raw materials. What’s more common is a machine can only use one type of material; hence a company trying to produce products made of different materials is forced to invest in various devices to use in the production process. However, the CNC machine easily accommodates the use of plastic and metal in the creation of prototypes hence drastically reducing the CNC prototyping cost

- CNC Machining Services Assures Fast Turnaround

Time management is a factor that is critical in manufacturing industries as it affects the number of products produced. However, in most traditional manufacturing plants, downtime is usually caused by a change in work shifts by employees or numerous breaks necessary for rest. But, you have the assurance of fast turnaround operation when contracting CNC machining services in China. With minimization of human involvement, there is a reduction in rest breaks needed, and the only downtime is for maintenance and upgrades hence guaranteed round the clock operation.

- CNC Machining Services Offers Controlled Precision

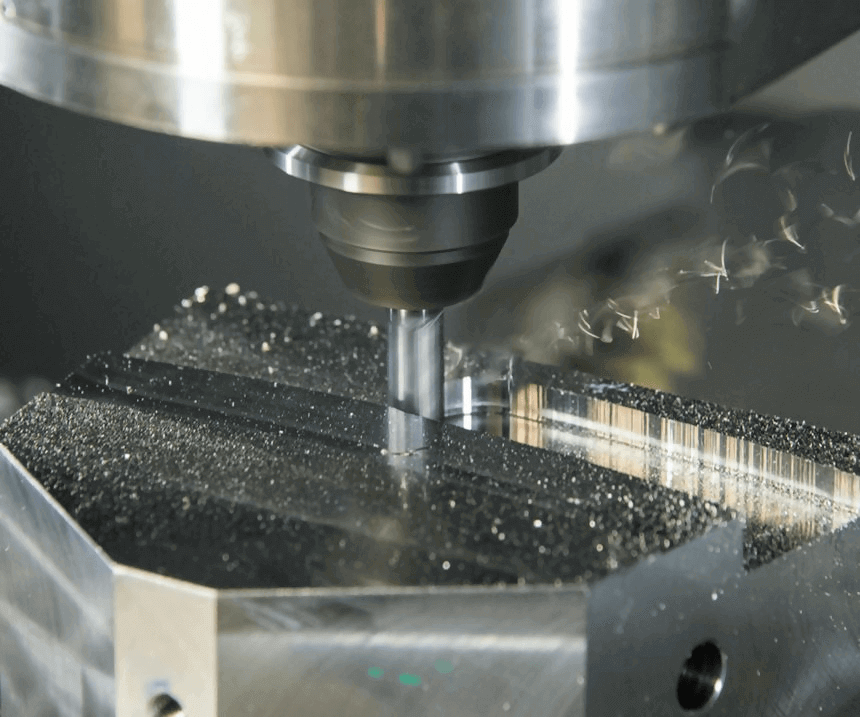

CAD technology is put in use to create a 3D model to ensure high accuracy in the manufacturing of a product. The 3D model allows designers to evaluate the function and look of the finished product accurately. When printing the prototype, the machine follows the software input generating a sample accordingly. As it factors every part beforehand, you are assured of precision with CNC machining as it uses controlled movements to provide accurate models.

- CNC Machining Services Is Scalable

Though the CNC machining services are mostly used in the creation of product testing samples, it can also be put to use for mass production of process. Ideally, once the primary sample is tested and gets an all-clear for production, the sample machine can be used to replicate orders. An engineer inputs new CNC machining orders in the software program allowing manufacturing of scalable volumes of up to 100,000 products efficiently.

- CNC Machining Services Requires Minor Human Involvement

Human involvement is necessary for the creation of new products. The association is especially required for the designing, engineering and testing process to ensure that the product created is usable. However, it is also a fact that many mistakes made during production are due to human involvement. Through the CNC service, you can cut down on human errors and only including employee interaction when necessary.

Conclusion

When it comes to the creation of prototypes, two main ways in use are the CNC prototyping and the rapid prototyping processes. Unfortunately, materials through the rapid prototyping process can be quite expensive and hence reserved for specific models. Nonetheless, as seen above, you can get quick, high-quality, detailed samples to use through the CNC machining services, saving you time and money.