The continuous spread of COVID-19 has an impact on the rapid manufacturing industry. Supply chains, coupled with markets, have been affected. As the number of affected patients who need treatment continues to increase, healthcare providers are experiencing shortages in essential equipment, with ventilators topping the list.

The World Health Organization reiterates that 75% of COVID-19 patients recover without the need for hospital treatment. But two in seven people become ill. In such cases, the coronavirus damages the lungs. It also causes the oxygen levels of the body to drop. This makes it hard to breathe.

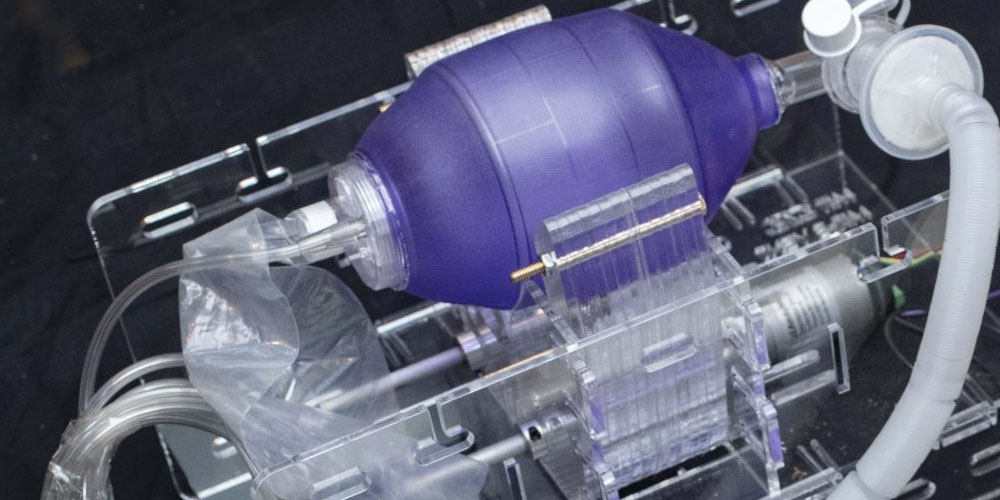

For this to be alleviated, a ventilator is used. It takes over the patient’s breathing system when the lungs fail. This gives a patient time to fight off the coronavirus and recover.

After realizing that there is a shortage, governmental calls to the rapid manufacturing sector have been made to help produce and mobilize ventilators from manufacturers to service providers.

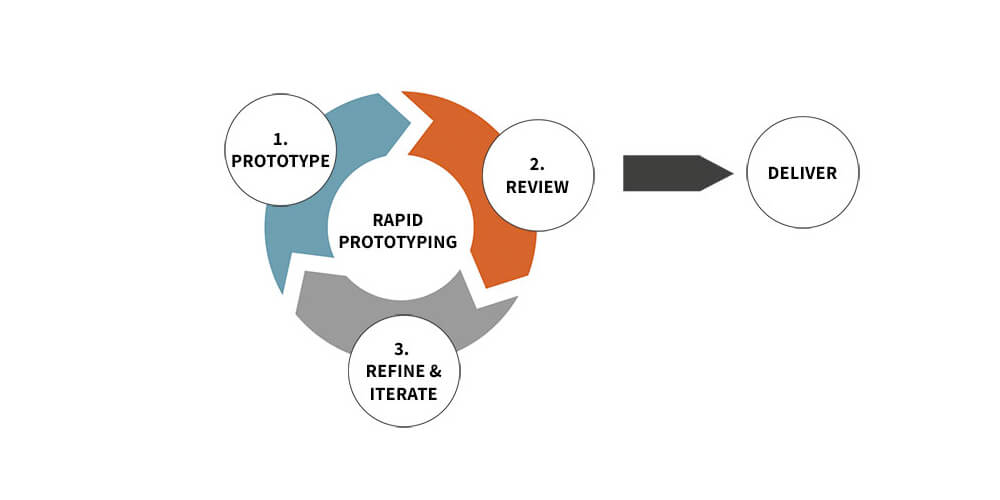

Additive manufacturing initiatives have also been spearheaded to help track the development of ventilators to meet demand. Simultaneously, networking sites such as LinkedIn have become the hallmark for sourcing solutions coupled with signal boosting devices of various local calls for assistance.

To help reduce the rising number of infections, Governments have reached out to rapid manufacturing industries to help in the production of ventilators and other PPE kits to support the healthcare industry.

Among them is the European Union, which just approached the Machine Tool Industry to produce equipment lacking in hospitals. Following this call to action, AM companies are using their skills to produce ventilators.

The government of the United Kingdom has also called on businesses, including those with RP skills, to send blueprints to ventilator manufacturers. Aerospace and automotive companies heed to this call by forming teams to manufacture ventilators.

According to healthcare researchers, one of the projects includes building a variety of oxygen systems for military aerospace applications.

The USA is reportedly going to connect the AM industry’s capabilities with the healthcare providers’ particular needs using an online repository.

When the month began, AM German AM companies spearheaded the acceleration of rapid prototyping services in transport to help reach out to patients who needed instant medical attention.

In just about three days of issuing the call, the healthcare departments reported having received support in materials and capacity from more than 200 RM companies.

The coronavirus spread has affected the world’s economy in many ways, including sending most furlough workers. That is why government officials are contacting RP companies to supply ventilators and other PPE kits.

Medical devices used to diagnose and treat coronavirus patients include diagnostic tests and ventilators. There is a vitro diagnostic test conducted on various samples of mucus swabs harvested from the nose for testing.

A blood sample can also be taken from the patient’s finger prick. It is important to note that testing is crucial to diagnosing coronavirus and getting accurate numbers.

Final Thoughts

As more hospitals in the world continue to face shortages in ventilators, engineers, and physicians across the world have partnered to find out how to make ventilators at lower cost.