Ether remains one of the actively traded cryptocurrencies in the global market, and its value against the USDT (Tether) provides a good understanding of how traders and investors perceive its real-time value. Since the USDT is a stablecoin tied to the US dollar, it can be utilized to study the performance of the Ethereum market without the interference of other, more conventional fiat currencies. The ethereum price usdt chart, therefore, is an essential tool in the process of learning about the price movement of Ethereum, in order to see the opportunities to trade and to invest in Ethereum depending on the facts.

Reading the Basic Structure of the ETH/USDT Chart

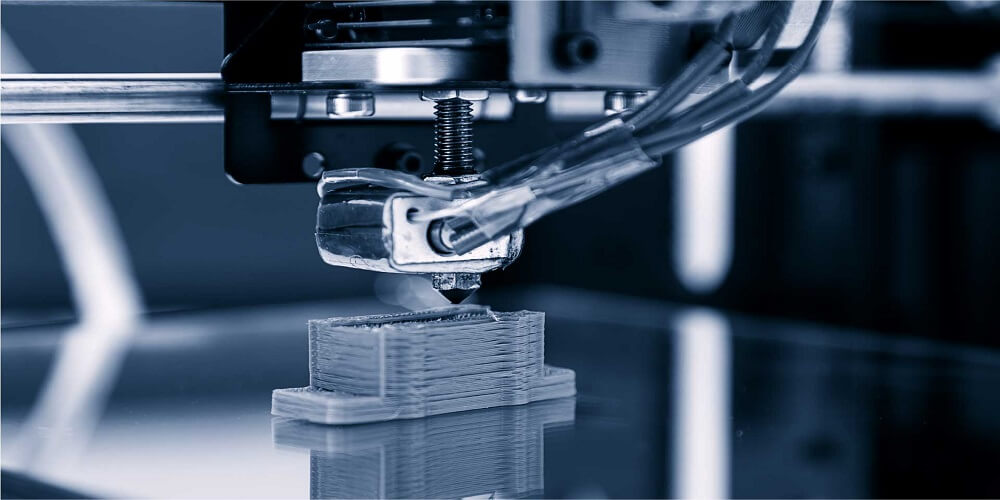

The initial move in the Ethereum price analysis is to get familiar with the coin’s ETH/USDT structure. This chart, presented with candlesticks that indicate price changes over a selected period of time, is shown in most trading platforms, including Bitget. In every candlestick, there is the open, high, low, and close price of Ethereum at a given time span, like one minute, one hour, or one day.

The green candles tend to represent an upward movement of prices, whereas the red ones represent a downward movement. It is common to see traders moving between the various time periods in order to capture short-term fluctuations or to see the long-term price formation. There are also volume indicators at the bottom of the chart, which show the level of active trading of Ethereum. When the trading volume is high during the rise in prices, it may be an indication that the momentum is very bullish, whereas when it increases during the fall in prices, it may indicate an increased selling force.

Identifying Key Support and Resistance Levels

The most important ideas to be relied upon in the analysis of the ETH/USDT chart are support and resistance. The support and resistance levels are the price levels where people have enough purchasing power to ensure that Ethereum does not keep falling, and the level where people have the desire to reverse the upward trend by selling power, respectively.

Ethereum regains its momentum and price when it approaches a support zone, and this indicates that the investors have regained confidence. Alternatively, traders are able to expect a pullback as it nears a resistance level. As Ethereum moves beyond resistance levels or support, over time, it moves, thus signifying new market conditions. Constant monitoring of these levels enables traders to predict the price trends and strategize on the same.

Making Informed Decisions Using ETH/USDT Data

The trend analysis of Ethereum using ETH/USDT charts can provide traders with practical information instead of speculation. Through observation of support and resistance, technical application, and identification of patterns, it is possible to construct a strategic approach to trading. To analyze successfully, I have to be patient, monitor constantly, and adapt to the changing market conditions.

Finally, ETH/USDT charts provide a clear picture of the actual performance of Ethereum. Being a day trader who wants to make a quick gain or a long-term investor who wants to evaluate the growth potential, the knowledge of how to read these charts is the key to ensuring a consistent outcome. The ability to follow the dynamics of Ethereum relative to USDT is one of the most effective instruments to make informed decisions and succeed in the long term in an ever-changing crypto market.

Recognizing Chart Patterns and Market Psychology

The chart patterns can be used as helpful hints regarding the future price of Ethereum. The regular patterns used, such as ascending triangles, head and shoulders, and double bottoms, are used to show how traders react to market sentiment. As an example, a rising triangle can be a good indicator of a bullish breakout, and a head and shoulders pattern can be followed by a price fall.

It is also important to know market psychology. When the market is in a bullish cycle, people have more buying power, which leads to an increase in prices. Fear and uncertainty would lead to sudden liquidations in bearish markets. Pattern recognition and emotional analysis will enable traders to predict the possible reaction of market participants in various situations.

Conclusion

The study of the Ethereum price through the ETH/USDT charts is a crucial aspect for a person who wants to move in the world of crypto with a sense of confidence and accuracy. These graphs offer an objective, data-driven view of the performance of Ethereum in comparison to a stable point of reference so that traders cannot tie their emotional reactions to strategic decision-making. With Ethereum continuously developing and shaping the overall digital economy, understanding ETH/USDT chart analysis is the key that enables traders to make smarter and timely decisions- and turns unprocessed data about the market into a trading signal that matters.