The medical industry is among the sectors that use the prototyped parts in its operations. The technology has advanced tremendously such that parts such as pacemakers can be developed. The growth in the medical industry has reduced the chances of death significantly. Also, parts such as hip replacements protect patients from using wheelchairs all their lives. Companies in the prototype manufacturing industry have been a lifesaver for most. Prototyping is found in many countries like prototyping china. This post aims at updating you on the Application of the prototyping process in the medical industry.

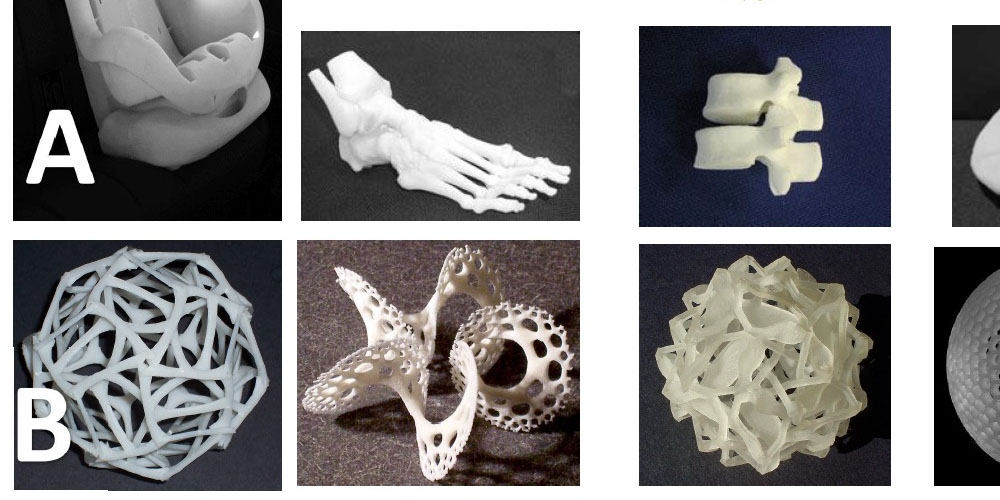

Examples of prototyped medical parts

- X-ray equipment

- MRI devices

- Ultrasonic equipment

- Medical monitor devices

Application of the prototyping process in the medical industry

There are four critical steps in developing medical devices

1. Alpha prototypes

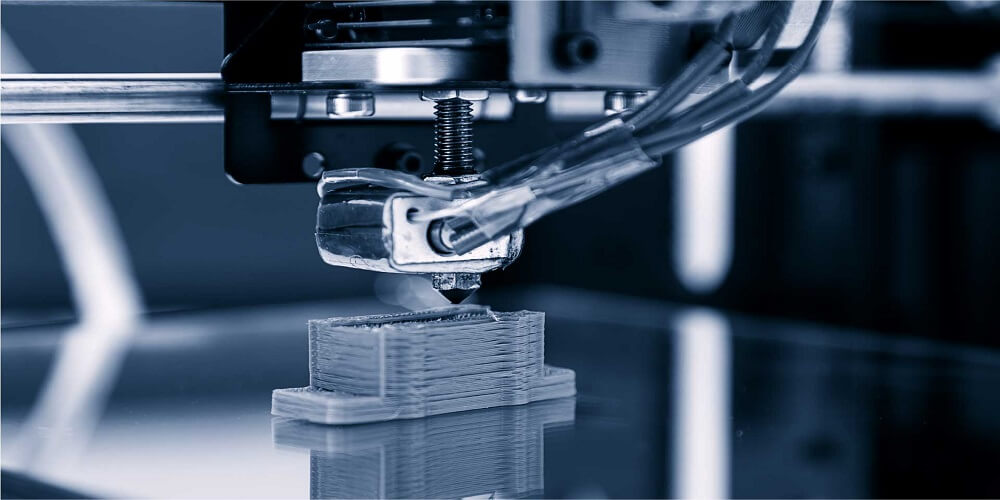

The first step in developing medical devices prototypes is the Alpha prototypes. At this step, the manufacturer utilizes a 3D printer to check out the medical prototype dimension. There is no actual production at this step. Therefore, you get to save time and money on the purchase of material and production services. The 3D printed medical prototypes are used to check whether every angle is done correctly and how it will appear once production commences. The 3D-printed medical prototypes at this step are non-functional.

2. Beta prototypes

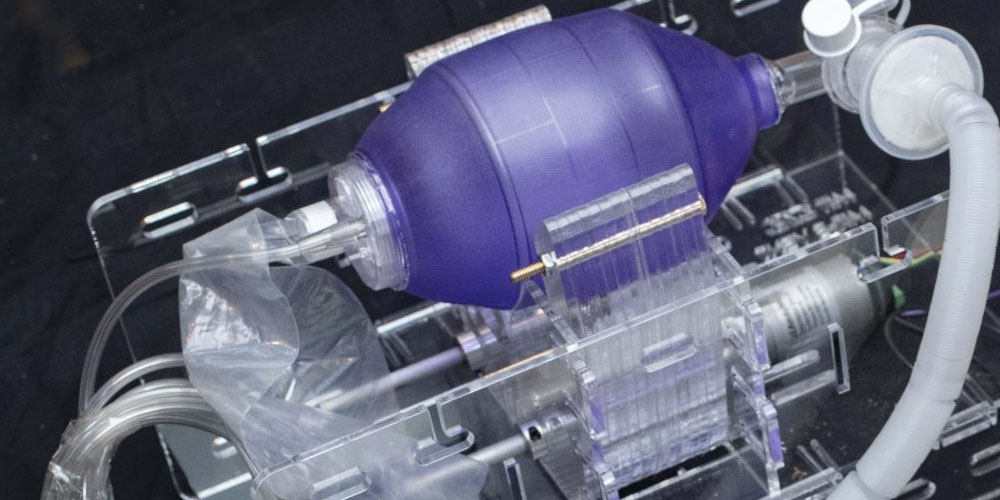

The second step involves the beta prototypes. The manufacturing method used at this stage is more refined. The main goal of this step is to check out whether there are any issues with the manufacturing processes and the design’s functionality. Compared to the alpha prototypes, the medical device prototype is functional at this stage, although its exterior design may not be the same as the expected output. Also, the prototypes used at this step can be used to seek out investors.

3. Pilot prototypes

The third step in the medical prototype developing process is the pilot prototype. The pilot prototype design is almost identical to the previous step, but it looks more like the final output. The medical prototypes manufactured at this step are mainly used for clinical trials and device launches. The prototype manufactured follows the precise material and design specifications.

4. Final product

The last step involves the production of the final product. This step ensures that the design is fully functional. In addition, it incorporates the previous steps and any modifications made to the design. This final step produces the final medical prototyped device.

Machining methods used to produce the medical prototyped device

- Vacuum Casting: This technique is best suitable for flexible and rigid parts. This method is very affordable, and it ensures that the surface finishing is very smooth.

- Aluminum machining: This technique allows manufacturing companies to develop products and prototypes of very high quality.

- Clear acrylic polishing and machining: This technique is used for products such as lenses. It ensures that the parts are created with high levels of precision and quality.

- CNC machining: This technique allows for the production of medical devices that requires a tight tolerance.

Conclusion

The medical industry cannot function as properly without the prototype development processes. Some of the equipment, such as the MRI equipment, is essential for running tests. The existence of prototyping allows for services in the medical field that would not have otherwise existed.