For many components and products made from metal, including cars and utensils, rust is a devastating condition. In rainy climates such as those of the United Kingdom and Brazil, metal surfaces rot and crumble away quite quickly when water is absently left to collect in any crevice present on the metal surface. The traditional ways of dealing with rust on metal components and products included grinding, cutting, and selective choice fabrication. However, the efficient application of a quality laser rust removal tool has been proven to be much more efficient and faster than all the other techniques combined. Laser rust removal works magnificently to clean up metal parts quickly. Let’s focus on the advantages of laser rust removal.

How the laser rust removal and cleaning works

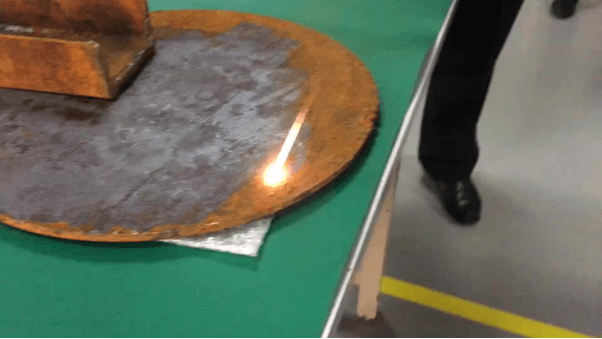

In general, the procedures involved in removing contaminants of various types such as oil, rust, and oxides from steel surfaces by utilizing laser technology are collectively called laser cleaning. Thus, to clean rust from a metal surface, lasers use ablation, where any surface that absorbs the laser beam light appropriately enough is heated to a plasma. For example, a carbon dioxide-based laser can generate up to 1000 Watts of power that can be focused on a spotless than one millimeter squared.

The metal surface that absorbs the laser rust removal tool’s wavelength is heated extremely fast, exposing the clean metal surface beneath. This cleaner metal surface then begins to reflect the remaining laser beams off the metal surface, preventing them from eating away at the iron underneath.

Advantages of laser rust removal

- The technology applied in laser rust removal tools is reliable and fast

Lasers enable the efficient and rapid cleaning of metal parts of various shapes by eliminating rust accumulated on their surfaces.

- Laser rust removal involves low consumable cost and low maintenance costs for the laser rust removal tools. Such tools and systems are so low-maintenance they have almost no consumable costs.

- Laser rust removal tools consume very little energy, and the new fiber laser cleaning techniques feature even lower electricity consumption rates.

- Improved productivity and versatility – the fact is, laser rust removal tools and associated cleaning systems are superior alternatives to chemical and manual rust cleaning methods since the trajectories of the laser beams can be quickly altered using software inputs.

How laser rust removal is possible

- It is always possible to remove contaminant material in a particular way – considering the presence of an ablation threshold for each material. Cleaners can distinguish between two or more layers when trying to remove an unwanted layer from a surface.

- Every material (including metals) has an ablation layer. In this instance, laser ablation occurs when a layer of rust deposited on a metal surface is easily removed by applying a laser beam from a laser rust removal tool.

- Laser beams are environmentally-friendly and consumable-free – the laser beams are only focused on the surface to vaporize the rust layer, meaning that the process has no consumables.

Conclusion

Laser cleaning is a fantastic new technology that is set to overcome many of the previous challenges that existed in the process of rust removal from metal surfaces. Laser rust removal tools are fast, clean, and efficient for metal cleaning.