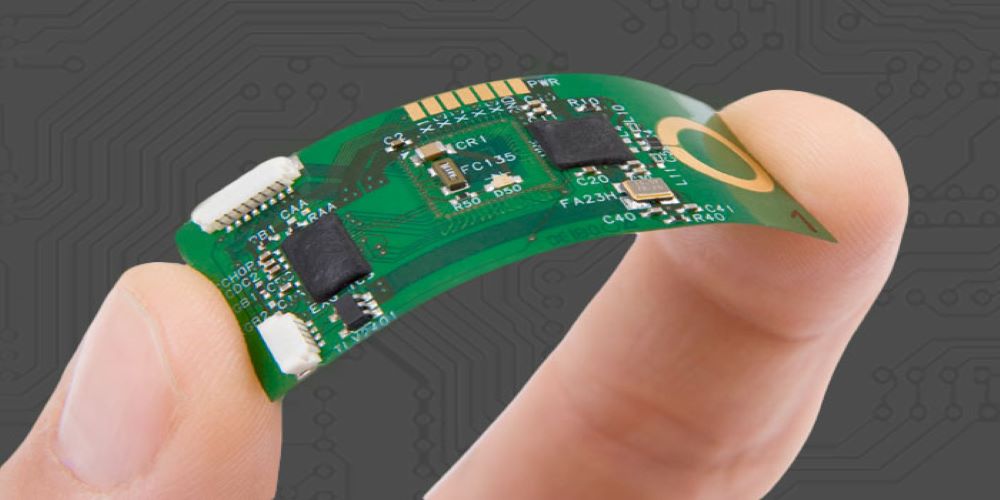

Flexible printed circuit boards (PCBs) are perhaps the most ideal solutions for all commercial electronics needs. Basically, a flexible PCB is a printed PCB that can flex freely. Because of this, they arise from different types with various features most particularly in manufacturing, design, and functionality.

Flexible PCB boards have been primarily used for several applications such as computer networking, industrial automation, medical equipment, telecommunications, and even the aircraft and transportation industry. In addition, several innovative technologies such as touch screen technology and electronic document scanning have also been applied to these boards. Because of its flexible nature, PCB manufacturers have been able to create different varieties such as full flex and half flex PCBs.

Half flex PCB is typically used in multi-board applications such as electronic data cards, flat sheets of memory chips, and communications systems whereas full-flex PCBs are widely used in high-volume audio and video applications and in several other industries. Besides, flexible printed circuit boards have also been successfully utilized in several different sectors such as chemicals, water purification, electricity, automotive, military, aerospace, and many others.

Easy-to-Install & Lightweight Flexible PCBs

The advantages of using flexible PCB in various applications are numerous. In particular, these flexible PCBs are capable of fitting into a different space required for various applications. For instance, they do not require any extra space for installation purposes and can be installed easily on the edges of different devices.

Another advantage of the flex circuit board is its lightweight feature, which makes it perfect for mobile applications. Moreover, these flexible printed circuit boards have also been found out to be quite effective in eliminating the risk of short-circuiting which is one of the most common failures observed in electronic components. In addition to this, they also offer greater flexibility in addressing fluctuating environments by offering the capability to change their position and connection directions when required.

Large Storage Capacity of Flexible PCBs

There are a number of advantages of using flexible printed circuit boards. As mentioned above, these types of boards have a larger storage capacity as compared to their fixed counterparts. Also, the smaller size of the flexible PCB allows for easy removal and modification without requiring the assistance of technical personnel. This allows for simple roll-off packaging and efficient shipping, which are vital for e-Commerce. Another advantage of flexible PCBs is that they are suitable for use in a wider range of electronic equipment and devices because of their ease of use.

Durability & Flexibility of Flexible PCBs

In general, there are many advantages associated with using a flexible printed circuit board. Due to the greater durability and flexibility, the reduction in defects and the increase in productivity have been seen as many benefits by manufacturers. Apart from this, the manufacturers have also seen the usage of such PCB in the healthcare industry. The PCBs used in this case is commonly used for medical applications because they are considerably more durable than the traditional rigid PCBs and offer a higher level of performance at a lower cost.