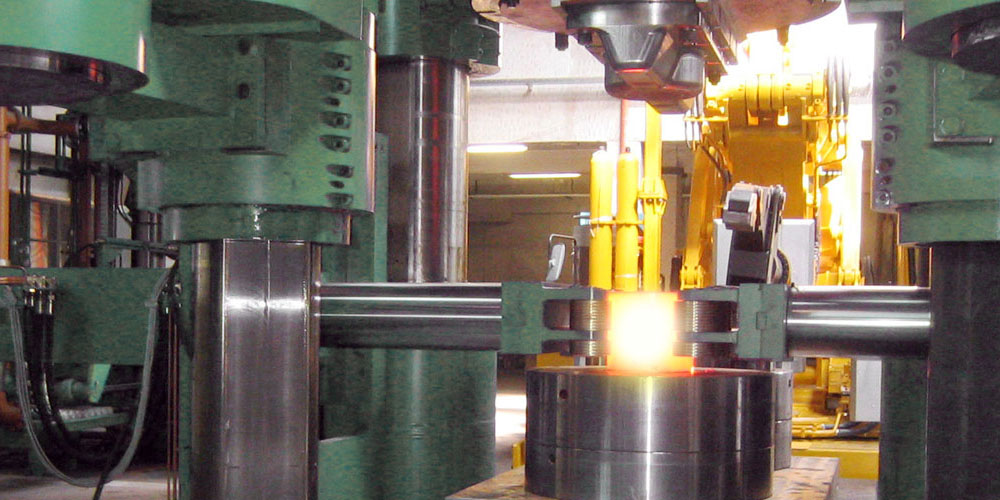

Choosing the right induction heating machine is an important process. It can be challenging to navigate, but it’s worth it; a good induction machine will last you for years and make your life easier in the kitchen. If you’re considering buying an induction heating machine, here are some features you should consider first:

Flexible power range

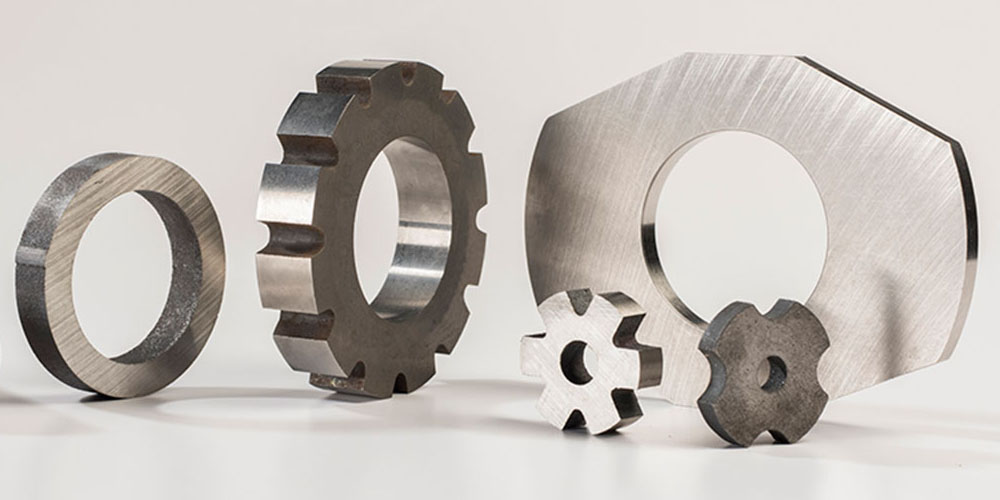

This is an important feature of your machine. The power range of induction heating machines should be flexible enough to cater to different applications. You do not want to buy a device that can only be used for high-power applications such as heating metals and plastics, as you will buy another machine if you wish to heat food or liquids. Therefore, you must consider the various power settings available when choosing an induction heating machine.

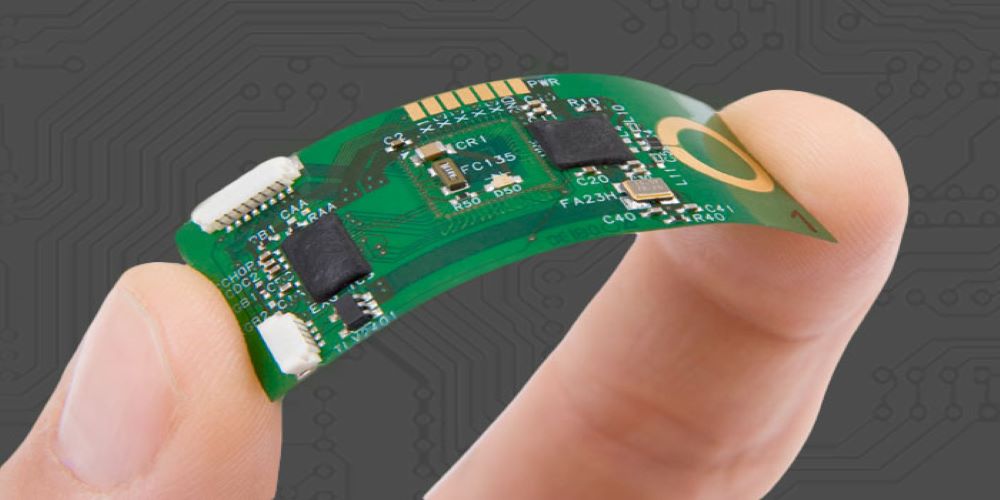

A good solid-state design

There are a few things you want to look for when choosing an induction heating machine. One of them is a good solid-state design.

A good solid-state design means the heating coil has no copper wire connecting it to a power source. Instead, it uses capacitors or other electronic components to create the current necessary for heating. This type of design is more efficient than one with copper wires because there will be less resistance between your material and its heat source, which enables better contact and faster heat transfer rates (which means you can have higher temperatures).

A bad solid-state design would be inefficient due largely to poor insulation materials used on connections; this can cause overheating if not well insulated properly (especially in cases where large amounts of energy are being transferred). Another problem could arise when using poor quality power supplies – they may not provide enough power needed for faster heat transfer times because they lack proper filtering technologies designed specifically for induction heating applications like yours!

Clean and reliable power supply

- A clean and reliable power supply is vital to the performance of your induction heating equipment.

- To test for a clean power supply, use an ohmmeter to measure the resistance between each phase (L1, L2, L3) and ground. The reading should be less than 5 ohms on all three phases. This means there are no grounds in the system, which could cause safety issues when using your induction heater. You can also use an inductance meter to check for high inductance levels caused by dirty power supplies or windings with low turn ratios.

- To maintain a clean power supply: regularly check that there are no grounds or other defects in your system; replace any faulty wiring; replace capacitors if they are more than 10 years old; if you notice any flickering lights while operating equipment powered by this system (e.g., fluorescent lights), immediately turn off all nonessential circuits until the problem has been resolved; never operate any equipment powered by this system without first testing it thoroughly for faults before putting it into operation.

Stable outputs

The first thing to look for is stability. You want a machine that can produce an output with a consistent and reliable power level. This is important for safety reasons and repeatability in what you’re trying to heat. If the power output varies from time to place or from place to place, your heating process will have less consistency and more variation than it needs to succeed.

Low maintenance design

When buying equipment, you should always look for something easy to maintain. While it’s great to have a machine that works well and never breaks down, it can be a pain if you spend so much time maintaining it. If you don’t want too much trouble with your induction heating machine, ensure it has a low-maintenance design.

Induction heating machines are very reliable and rarely break down. This means there is less maintenance required for them compared to other machines, such as gas or electric heaters, whicreplacementregular cleaning or replacing parts like fans or belts every few years due to high operating temperatures (over 1000 degrees Fahrenheit).

Conclusion

Knowing what you need before choosing an induction heating machine is important. These machines can be expensive, so it’s important to make sure you get one that will last and be able to handle whatever job you need it for. If you don’t know what features are important when selecting the right machine, it’s easy to end up with something that doesn’t meet all your needs or expectations. This article should give you some good ideas about choosing wisely when shopping for an induction heating device!