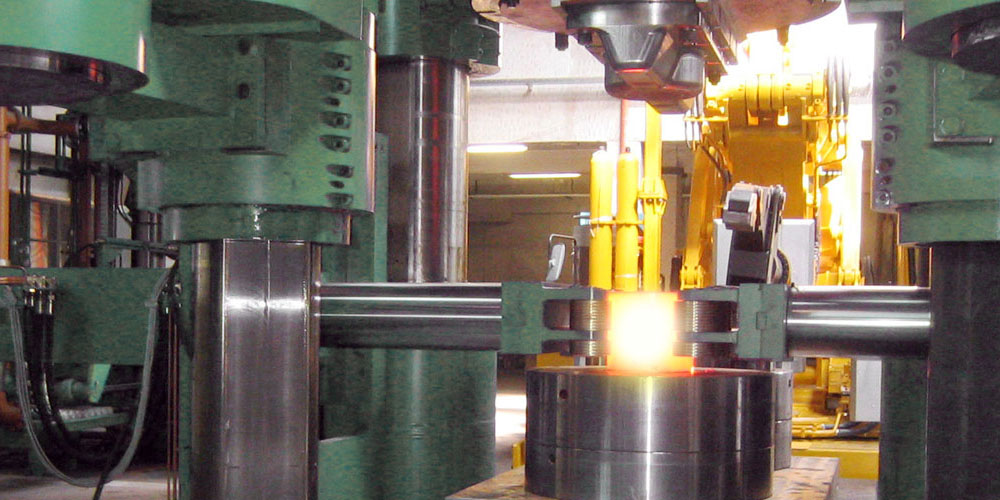

Hot forging press works by slow continuous application of force. The hot forging press is different from drop-hammer forging, which applies force instantaneously. Furthermore, in the hot forging press process, the time a die spends while in contact with the metal is calculated in seconds. Other forging methods, such as drop forging, calculate the time in milliseconds. Furthermore, the hot forging processes are pretty straightforward. If you wish to learn more about hot forging, click here. Also, if you want to learn more about hot forging press, here are five essential questions to ask.

Five essential questions to ask about hot forging press

1. What is plastic deformation in hot forging press?

The first question you should inquire about while learning more about the hot forging press is plastic deformation. Plastic deformation in hot forging press can generally be described as a permanent deformation that happens when a metal is exposed to compressive, tensile, and bending stresses that go beyond its yield strength and ensure it compresses bends elongates twists, and buckle. Therefore, learning more about plastic deformation will help you in knowing more about the hot forging press.

2. What is the best method to use to clear off oxide scale from the hot material surface prior to the hot forging press?

When heating the metal in temperatures of up to 1200 degrees Celsius, the workpiece surface starts to rupture because of iron oxidation. Thus, during the deformation, the oxide coat enters the workpiece surface when compressive forces are used. Therefore, it is essential to inquire about the best method to clear off the oxide coat from the hot material surface before the hot forging press commences.

3. Does the hot forging press deform an entire workpiece?

Other forging techniques like the drop hammer forging deforms only the workpiece surface that contacts the anvil and the hammer, ensuring that the workpiece interior remains undeformed. Therefore, it is essential to inquire whether the hot forging press will deform the entire workpiece or just the surface. Generally, the hot forging press allows for whole workpiece deformation. Also, the hot forging press process controls the compression rate, thus ensuring that the workpiece’s internal strain is controlled.

4. Is hot forging press economic?

The question of whether hot forging press is economical is an essential question to ask. Generally, hot forging press is beneficial in high productivity because the forging processes are very economical. In comparison to other forging processes, hot press forging are more economical in high productivity. Furthermore, the hot forging press is economical because it establishes closer tolerances.

5. What part size can the hot forging press make?

The Hot forging press machine size allows for the machine to make any part size you may need. Therefore, the hot forging press does not have any limitations in creating different shapes and sizes. Also, new innovations in the hot press forging methods allow for a high degree of mechanical integrity.

Conclusion

Inquiring about that hot forging press can help you understand more of the process and the quality of the outcome of a part. It can also help you decide the forging process you wish to be applied to your metal. Thus, the above are only a few questions to ask if you wish to learn more about the hot forging press.